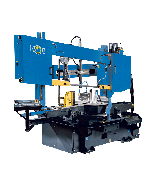

DS-500SA Dual-Miter Semi-Automatic Band Saw

Machine Capacity: w 19.5” x h 13" (495mm x 330mm

Round Tube: 14″ (356mm)

Production Level: Intermediate/Medium

Standard Features: Variable Vise Pressure Control, Work Light and Mist-Style Band Lubrication

The DoALL DS-500SA StructurALL® semi-automatic, dual-miter metal-cutting band saw is designed for cutting material both linear and at angles.

Also classified as a horizontal “scissor saw,” the DS-500SA is ideal for machine shops, metal service centers, repair facilities and industrial manufacturing plants that need to cut structural metal, tube and profile material. Miter angle cuts are possible up to 60° left and right, making the DS-500SA an invaluable addition to your team.

A Mitsubishi digital readout comes as standard and makes it easy to verify exact cutting angles and set operation parameters. The operator is also removed from the saw blade and moving parts during the cut -- providing additional safety and comfort.

A wide range of accessories are included with your new DS-500SA to get you cutting in no time:

- Dual swivel head to 60 left to 60 degrees right

- Semi- Automatic cycle

- Movable control console

- Rapid head down approach

- Carbide faced saw guide inserts

- Programmable material height sensor

- Full stroke hydraulic vise

- Driven band cleaning brushes

- Infinite band speed controlled by variable frequency drive

- Heavy duty counter balance springs

- Cast Steel band wheels

- Fine adjustment head feed control

- Spring loaded detent positioning

- Manual band tension.

- Recirculating coolant system.

- Mist band lubricator system.

- Digitally displayed angle position.

- Variable Vise Pressure.

- 2 degree cant design.

- Saw blade guards.

- Band door interlocks.

- Operation and parts manuals on USB stick.

- Recommended band speed chart.

- One (1) complimentary DoALL Bi-Metal saw blade.

- Complimentary DoALL Cutting Fluids package.

Machine Details & Specs:

- Operator Control Console - Control console can be positioned for operator comfort and safety insuring hands are away from the blade at band start.

- Mitsubishi Touch Screen Panel - The touch screen control panel displays the cutting cycle indicator, blade tension indicator, BRP (overfeed protection) function, band speed, head angle, band drive amp load, and a list of error messages allowing the operator to monitor machine functions.

- Saw Head Design - The robust head is mounted at a 2-degree slope which decreases tooth load at the end of the cut increasing band life.

- Direct Driven Band Drive - Drive is comprised of an electric VFD controlled motor transferring power through a gear reduction unit directly to the drive wheel eliminating belt slippage and giving positive torque to the blade.

- Semi-Automatic Cycle - Programmable cycle allows the operator the ability to control hydraulic on-off, saw head movement after the cut, head raise limit through programmable set point, band drive on-off, and vise clamp-unclamp after the cut maximizing productivity.

- Automatic Overload Feed Protection - BRP function monitors band drive motor amperage stopping head fall when operator set parameter is reached signaling overfeed or a dull saw band.

- Band Wheels - Cast steel wheels insure band tracking and long life.

- Hydraulic Clamping Vise - Full stroke, hydraulic vise can be positioned on either side of band allowing maximum clamping close to the cut line eliminating material movement and tooth strippage.

- Manual Blade Tension - Illuminating indicator prevents the possible error of over/under tightening the band for maximum cutting rates and band life.

- Band Brush - Driven band brush removes the chips from the blade gullets which would prevent the blade from attaining maximum cutting rates and blade life.

- Counter Balance Springs - Counter balance springs maintain constant head weight throughout the cut keeping the blade tooth load equal aiding in maximum blade life.

- Head Turn Table - Manual position of the saw head is accomplished by releasing the lock mechanism and rotating the head to the desired angle monitored on the digital display. The machine is equipped with a spring-loaded detent for zero position allowing for decreased setup time.

- Warranty - One-year parts only subject to the terms and conditions. Optional ten-year available DoALL Cut Above 10 Year Warranty

Specs:

Saw Blade:

- Width x Length – 1.25" x 188"

Band Drive:

- Motor HP - 4 Hp

- Band Speed - 65-328 fpm

- Band Tension – Manual

Hydraulic System:

- Motor Hp - .5 Hp

- Reservoir Size - 3 Gallons

Coolant System:

- Motor Hp - .6 Hp

- Reservoir Size - 5 Gallon s

Indexer:

- Length per Stroke - N/A

- Maximum Index Strokes Length - N/A

- Remnant Length - N/A

Floor Space Dimensions:

- W x L X H - 114" x 43" x 56"

- Material Pass Height - 32"

- Machine Weight - 1,631 lbs.

Electrical:

- Voltage Requirement - 230V or 460 -6 0Hz-3ph, Wye configuration (Must Specify at Order Placement)

- Total Amp Draw (FLA)(460V - 7) (230V - 14)

Optional Accessories:

- 6.6 ft (2000mm) Heavy-duty input conveyor for angle cutting with drip pan/gutter - 20.5" (520mm) roller width - 1142 lbs/ft or 1700kg/m capacity

- 6.6 ft (2000mm) Heavy-duty output conveyor for angle cutting with drip pan/gutter - 20.5" (520mm) roller width - 1142 lbs/ft or 1700kg/m capacity

- 6.6 ft (2000mm) Input or output conveyor with drip pan/gutter - 20.5" (520mm) roller width - 672 lbs/ft or 1000kg/m capacity

- 5 ft Idler Conveyor

- 10 ft Idler Conveyor

- Additional conveyor roller

- Single fixed vertical guide roller - 20.5" (520mm) roller width - 7.9" (200mm) height - Mounts to the RDT

- Single adjustable vertical guide roller - Requires RB for operation

- Hydraulic vertical clamp for nesting

- Laser line generator

- 5 ft. Tape work stop (Mounts on Conveyor)

- 10 ft. Tape work stop (Mounts on Conveyor)

- 5 ft. Digital work stop (Mounts on Conveyor)

- 10 ft. Digital work stop (Mounts on Conveyor)

- Wear parts service kit - contains wear plates, guides, band brushes

- Magnetic wand chip remover

- Additional USB stick of manuals

- A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards

- Four (4) hours installation and operator training

- DoALL Cut Above 10 Year Warranty Annual Investment