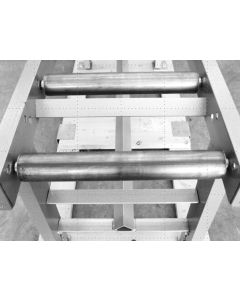

Roller Tables for Band Saws

-

207710 - CONVEYOR - 10 FOOT$4,444.05

-

218911 - CONVEYOR - 10 FOOT$4,830.00

-

224994 - CONVEYOR - 7 FOOT FOR DC-460$2,600.00

Conveyor Rollers

Roller conveyor systems are industrial maneuvering equipment that strategically transports products throughout a manufacturing or distribution facility. When paired with a band saw, these conveyors allow for quick and easy takeoff from the cutting area, providing increased efficiency to a saw-cutting operation. At DoALL, we offer various conveyor roller systems and parts to help optimize your company's production.

What Is a Conveyor Roller?

A conveyor roller is an integrated system of rollers that carries an item along a path using electricity, gravity or manual force. Conveyor systems typically consist of several major components, including:

- Rollers: These are the metal rollers that insert into the frame. They typically consist of a metal axis and several bearings for oscillation. The rollers are the part of the conveyor that carries a product or material to its destination.

- Frame and legs: The legs and the frame of a conveyor determine the system's path. The frame secures and houses the rollers, while the legs provide it with adequate support.

- Bends: A conveyor bend is essentially a curved frame. These sections allow a conveyor system to travel around an obstacle or in a more efficient direction for transport.

When an effective conveyor system combines with an industrial band saw, it speeds up the operation by eliminating the manual labor needed to clear the product away from the sawing area after it's cut.

Conveyor Rollers for Sale From DoALL Sawing Products

While some of our conveyors work specifically with certain saws, we also offer systems and components that are universal for many types of our machines. Most of our conveyor sections come in 5-, 7- or 10-foot increments. In addition, we sell rollers separately if you ever need a replacement.

When considering conveyor rollers for your application, some things you might want to think about are:

- Do you have any bottlenecks in your process?

- Do you already have a system in place? If so, does it provide the efficiency you need?

- How many employees does it take to complete the process?

- What type of material do you cut, and how long does each cut take?

If you require a conveyor roller system specific to your unique application, our team can help you put together custom options.

Benefits of Using Conveyor Rollers With a Band Saw

Implementing a conveyor system into your operation's manufacturing process comes with several advantages, including:

- Savings on labor: Conveyors eliminate the need for extra lifting after an item is cut and can often decrease the personnel needed for packing or unitization.

- Faster speeds: Over extended periods, automation beats manual labor every time. Conveyors offer greatly improved rates compared to transporting products by hand.

- Safety and improved ergonomics: An effective conveyor system decreases the need for frequent bending and stretching when carrying materials, creating a much safer and more ergonomic work environment.

- Improved organization: Rather than having a product pile up in an area near a machine, a conveyor system transports pieces where they need to go on time, promoting more optimized space utilization.

Shop Conveyor Rollers at DoALL Sawing Products Today

For more than nine decades, DoALL has provided the most cost-effective solutions to our long list of satisfied customers. Let our experts help you determine the best roller conveyor system for your operation. Add conveyor rollers to your shopping cart, complete our parts assistance form or call us at 888-362-5572 today.