Diamond Band Saw Blades

Diamond Band Saw Blades

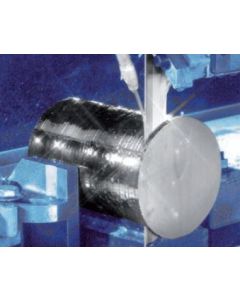

DoALL's diamond band saw blades are the first choice for cutting brittle and friable materials like glass, natural stone and other abrasive materials. These blades can handle unique cutting tasks when most general-purpose blades fail. However, it's crucial to remember that these specialty blades are inappropriate for steel-cutting applications.

What Are Diamond Band Saw Blades?

While the overall shape of a diamond band saw blade is similar to most other blades, it's unique because of the diamond grit on the edges. We apply this coating through a process that allows the diamond matrix to stay in place. A hardened back ensures long blade durability.

At DoALL, we manufacture several diamond band saws that fit our specialty saw category. We equip these saws with enhanced features like t-slots in the table and heavy-duty band guides to ensure complete control during the cutting process. Some of our models feature an integrated coolant system to keep the diamond blade cool while cutting.

DoALL Band Saw Diamond Grit Blades

DoALL offers Grit Edge Diamond Blades that pair well with all of our diamond band saws. We manufacture these blades in continuous forms for materials up to 25 millimeters thick and in a segmented design for larger materials.

Continuous-edge diamond grit band saw blades have grit along the entire length of the blade to cut thin and brittle materials, including stone, ceramic and glass. They leave a cleaner edge and are better suited for less aggressive cutting than segmented blades.

Segmented blades have diamond grit on the cutting teeth but not the gaps in between. These blades can make aggressive cuts on thicker and denser materials but are unsuitable for cutting steel.

Diamond Grit Band Saw Blade Applications

In most cutting processes, matching the blade to the material you're cutting is critical. Industries that use our diamond band saw blades range from ceramics fabrication to aerospace manufacturing to recycling. Some of the most common applications of diamond band saw blades include cutting materials such as the following:

- Glass

- Silicone

- Graphite

- Coal

- Ceramics

- Concrete

- Minerals

- Cinder

- Natural stone

- Perforated bricks

Benefits of DoALL Band Saw Blades

As a leading saw blade manufacturer with over nine decades of experience, we take the necessary measures to ensure our blades meet the highest accuracy, durability and quality standards. Some of the advantages of using our diamond grit blades include:

- Continuous rim blades offer higher quality finishes and longer life spans than conventional blades.

- Diamond blades provide exceptional ability to limit flaking and prevent dust.

- Flat and continuous blade surfaces eliminate shock and vibration to prevent unwanted chipping.

- Diamond blades provide accurate cuts to reduce product waste.

Shop Diamond Grit Bandsaw Blades at DoALL Sawing Products Today

At DoALL, we're committed to offering you the best possible advice for improving the performance and efficiency of your operation. Our knowledgeable and experienced team stands ready to guide you through all your blade purchasing decisions, whether you need a diamond blade, a bi-metal blade or a carbon steel blade.

Complete our quote or information request form today to get started.