Semi-Automatic

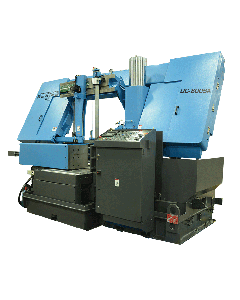

Dual-Column Semi-Automatic Band Saws

If your saw cutting requirements prioritize versatility and cut accuracy over high speed and larger volumes, then a dual-column semi-automatic band saw may be your best bet. Though these machines do not offer auto-indexing, they still deliver some of the fastest speeds for semi-automatic models. These designs can save you a significant amount of upfront costs compared to other devices that feature automatic cutting cycles.

What Is a Dual-Column Semi-Automatic Band Saw?

One of the most significant features of a dual-column bandsaw is its stability. The double columns are much more rigid than pivoting saws, allowing them to reduce vibration and workpiece movement when cutting. These advantages produce better cut quality, higher feed rates and much longer blade life.

A semi-automatic band saw means that the machine controls the head movement while the operator feeds the material. The operator typically secures the workpiece in a vice and watches the saw perform the cut, then return to the upper position on its own. These saws are perfect if you need to make multiple cuts on the same piece.

Types of Dual-Column Semi-Automatic Saws We Offer

DoALL offers several designs of dual-column semi-automatic band saws, including multiple models in our featured Continental Series™. These saws include a programmable logic controller for all hydraulic and electric functions and a flushing hose with auxiliary nozzles to streamline blade cooling. A blade breakage detector increases operator safety levels.

The DC-1700SA is our most expansive semi-automatic design, with the ability to cut tubes up to 51 ¼ inches in diameter. With a 13-inch round capacity and a 15 ¾-inch width maximum, the DC-330SA provides a more economical option for applications with minimal cutting requirements. We also offer several intermediate models so you can choose the ideal machine for your needs.

Dual-Column Semi-Automatic Band Saw Applications

Our extensive selection of dual-column saws lets you find the perfect match for the material thickness and density you typically cut. The larger saws in the Continental Series™ can handle a broad range of materials, including metals like aluminum, carbon steel, titanium, stainless steel and nickel alloys. The semi-automatic feature is ideal for applications without high production or indexing requirements.

The automatic head movement and auto-shutoff features further enhance operator safety. These designs are perfect for:

- Performing cuts on large workpieces.

- Providing superior stability and accuracy.

- Making multiple cuts in the same workpiece.

- Handling various shapes, like squares, cylinders, rings, shafts, flats and other odd designs.

Benefits of Industrial Dual-Column Semi-Automatic Saws

Whether your application involves cutting heavy-duty thick metal or thinner pieces of less-dense material, our semi-automatic saws can help improve the accuracy of your cutting operation while increasing your overall cost savings. Advantages of purchasing these machines include:

- Flexibility: Our dual-column semi-automatic saws can handle a diverse range of materials.

- High quality: These saws deliver increased stability and cut accuracy, whether you're cutting thin plastic or thick steel.

- Safety: The shutoff switches, door interlocks and blade motion detectors promote higher operator safety levels.

- Productivity: Dual-column saws take the shortest route through your workpiece, increasing the efficiency over pivoting horizontal saws.

- Less waste: Higher-precision cuts mean less spoilage, resulting in increased cost savings for your business.

Find Your New Dual-Column Semi-Automatic Saw at DoALL Today

At DoALL Sawing Products, we pride ourselves on offering the market's highest-performing cutting tools backed by superior customer service. Our professional staff has the knowledge and expertise to help you find the perfect cutting solution for your unique application. Fill out a quote request form today to obtain pricing and learn more about our dual-column semi-automatic options.