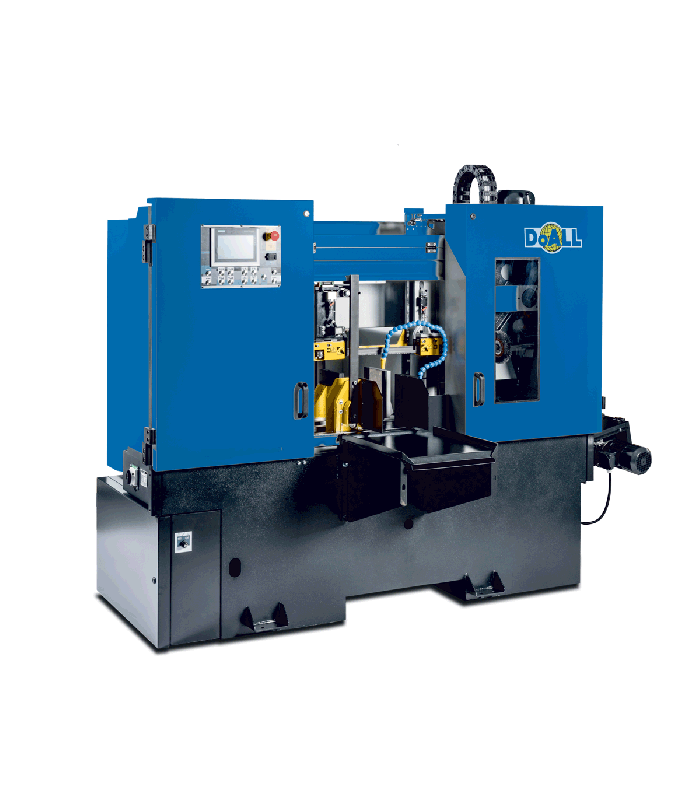

DC-300CNC - Dual Column Enclosed CNC Band Saw

Machine Capacity: w 12” x h 12″ (300mm x 300mm)

Round Tube: 12″ (300mm) | Round Solid: 10″ (250mm)

Production Level: Extreme

Standard Features: Siemens Touch-Screen Digital Controller (PLC), Automatic Programmable Feed Control and Variable Vice Pressure Control

The DoALL DC-300CNC Hercules™ high production, horizontal CNC band saw is highly efficient, automatic and hydraulically operated.

Designed for horizontal cutting of material only, the DC-300CNC is the benchmark for rapid production in industrial settings. Thanks to the robust construction of the dual column design of the DC-300CNC, it is possible to cut a wide range of full and profile materials including stainless and tool steel.

In addition, the "box" or enclosed design provides safe operation for high-traffic production facilities. A variety of optional accessories are available to customize the machine for specific sawing requirements.

Standard equipment and features for your new DC-300CNC -Dual Column Enclosed CNC Band Saw:

• Colored Siemens touch screen.

• Automatic & semi-automatic cycle.

• Worm chip conveyor for long chips.

• Rapid head down approach.

• Carbide faced saw guide inserts with lead in bearings.

• Programmable material height sensor.

• Full stroke hydraulic vises.

• Electric driven band cleaning brush.

• Infinite band speed by variable frequency drive.

• Split front vise.

• Cast steel band wheels.

• Programable modified metered feed system.

• 19" discharge table

• Hydraulic band tension.

• Recirculating coolant system.

• Variable Vise Pressure.

• LED work light.

• Saw blade guards.

• Band door interlocks.

• Automatic retraction of material in cycle for protection of carbide blade.

• Automatic guide arm setting.

• Operation and parts manuals on USB stick.

• One (1) complimentary DoALL Bi Metal saw blade.

• Complimentary DoALL Cutting Fluids package.

Details:

- Rapid Indexer Positioning-The indexer position is constantly monitored on the touchscreen. In a manual cycle, the operator can quickly position the indexer to a known position and move the material forward to be cut to length. This GTO function gives the operator hands-free material positioning insuring their safety.

- Direct Driven Band Drive-The drive is comprised of an electric VFD controlled motor transferring power thru a gear reduction unit directly to the drive wheel eliminating belt slippage giving positive torque to the sawblade.

- Hydraulic Indexer-The indexer is driven by a hydraulic cylinder/DRO system which is known for its accuracy. The 19.9” single stroke of the indexer can be multiplied up to 393”.The indexer is also capable of incremental indexing for short, slugging operations greatly reducing cycle time increasing production.

- Full Stroke Hydraulic Vices-Full stroke hydraulic vices insure maximum part clamping eliminating the possibility of material movement. The uniquely designed split front vice jaws provide maximum pressure near the cut at all times. Variable vice pressure will prevent distortion in thin wall tubing and extrusions when clamping.

- Floating Shuttle Type Index Vice-The index vice base "floats" allowing it to freely position itself when crooked stock is encountered reducing the possibility of inaccurate indexes due to material slippage eliminating waste.

- Automatic Material Indexer Retraction-Energizing the CMU function in the automatic cycle allows the indexer to retract material away from the blade before the head raises in the cycle. This greatly reduces damage to the saw blade teeth.

- Multiple Machine Cycles-The machine can be operated in either semi-automatic or automatic mode:

In semi-automatic mode, the material is positioned by the operator either manually or by use of the GTO function and clamped in place.

In the automatic mode the operator programs the pieces to be cut in one of 99 jobs, sets the material either manually or by use of the optional ATB function, and starts the cycle. The machine automatically cycles thru the parts as programmed making it a “hands-free” operation. - Hydraulic Band Tension-The tension is set automatically eliminating the possibility of over/under-tightening of the saw band allowing for maximum cutting rates and saw band life.

- Flood Coolant System-Supplies coolant to the blade evenly before and after the cut creating straighter cuts and allowing for longer band life due to the cutting fluid being applied at the tooth tip. A flushing hose is also attached to the system to allow for easy machine clean-up.

- Automatic Guide Arm Setting-The left hand saw guide arm is automatically set when the split front vice is clamped keeping the left-hand saw guide as close to the cut as possible reducing the possibility of band fatigue lengthening band life.

- Full Enclosed Design-Unique "saw in a box" design captures most of the mess associated with band sawing keeps the saw area clean. This increases operator safety by keeping their hands away from the moving parts of the saw.

- Multiple Work Height Settings-The machine's work height can be set in several ways. The first is by use of a work height sensor which allows the feed mode of the saw to be activated when it touches the material. It also stops the sawhead above the material at head raise shortening cycle time. The second way is the operator has the opportunity to program the head raise height when writing the program. The head stops at a programmed height by use of a DRO which is known for its accuracy. The head can also be programmed to stop at a given dimension allowing for the possibility of “notching” operations which can save valuable materials.

- Modified Metered Feed System-The metered cutting feed rates are regulated by the use of a hydraulic throttle valve which is controlled by a servo motor that allows for a very precise feed rate. This rate is monitored by the system using 2 programmable operator inputs ARP and RZP.

ARP is an operator setting that allows the machine to regulate the feed rate depending on-resistance of the material or dulling of the saw blade decreasing the chance of out-of-square cuts.

RZP is an operator setting allowing for the setting of optimal feed rates depending on the saw band position in the material. Rates and band speeds can be automatically sped up or slowed down to create a constant tooth load decreasing blade wear and harmonic vibrations to increase productivity. - Material Library-A vast material library is onboard which will automatically set band speeds and feed rates for entered materials. The library will also suggest needed sawblade configurations for either Bi-Metal or Carbide saw blades.

- Band Wheels-Cast steel bandwheels insure proper band tracking and extended band life.

- Band Change Safety Lock Out-A key activated lockout insures the band cannot be started while the operator is changing the band. It allows for minimum access to certain functions that may be necessary to change the band. When the key is deactivated a programmed blade break-in procedure automatically takes over insuring a good break-in of the saw blade increasing saw blade life.

- Warranty-One year parts and service subject to terms and conditions listed on the last page.

- An optional ten-year warranty is available. See Details Below.

Specs:

Saw Blade: Width x Length 1-1/4 " x 178"

Band Drive:

- Motor HP- 5 Hp

- Band Speed -65-328 fpm

- Band Tension-Hydraulic

Hydraulic System:

- Motor HP- 1 Hp

- Reservoir Size 16 Gallon

Coolant System:

- Flood coolant & Mist Lubricator Optional

Hydraulic Motor: .07 Hp

Reservoir Size 5.25 Gallon

Indexer:

- Length per Stroke 19.9"

- Maximum Index Strokes Length 394"

- Remnant Length 2"

Floor Space Dimensions:

- W x L X H 103" x 67" x 85"

- Material Pass Height 31.5"

- Machine Weight 3,131 lbs.

Electrical:

- Voltage Requirement 460V-60Hz-3ph, Wye configuration

- Total Amp Draw (FLA) 11.15 Amps

Optional Accessories:

- 3.3 ft. Output conveyor with plates between the rollers - 17.75" cyl width - 672 lbs/ft capacity (12-16 week lead time)

- 6.6 ft. Output conveyor with drip pan/gutter 17.75" cyl width-672 lbs/ft capacity (12-16 week lead time)

- 5 ft. Medium-duty idler conveyor 12" between frames roller capacity 850 Ibs

- 10 ft. Medium-duty idler conveyor 12" between frames roller capacity 850 Ibs

- Dynamic adjustment of feed rate to insure cut squareness (12-16 week lead time)

- Wear parts service kit - contains, guide inserts, band brushes

- Chip pan with drain

- Handle for chip box

- Magnetic wand chip remover

- Additional USB stick of manuals

- A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards

- DoALL Cut Above 10 Year Warranty Annual Investment