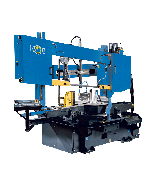

S-320CNC Automatic CNC Swivel Band Saw

Machine Capacity: w 12.5" x h 11.75" (320mm x 300mm)

Round Tube: 11.75" (300mm)

Production Level: Low/Medium

Standard Features: Touch Screen Digital Controls, Fully Automated Operating, Mitering Saw Head and Ball Screw Feed

The DoALL S-320CNC automatic metal-cutting band saw is ideal for fabricating shops, maintenance facilities, tool and manufacturing plants. The S-320CNC is a horizontal StructurALL®, scissor-style miter-cutting saw for low to medium rate production.

Hydraulically controlled, this CNC machine provides automatic indexing for multiple material feeds. With the easy-to-use Mitsubishi digital touch controller, operators simply program their desired cut and then remove the finished product. The DoALL S-320CNC is ball screw driven by a 3.5 hp motor. Designed for vertical and angular cuts, the S-320CNC is adjustable to 60° in semi-automatic mode, only.

S-320CNC Swivel-Head Bandsaw

Looking for a high-performance swivel-head bandsaw for sale? If your operations require precision cutting, versatility, and efficiency, the S-320CNC Automatic CNC Swivel Band Saw is the solution you’ve been searching for.

Designed for businesses that need to stay ahead in the competitive world of metal fabrication, this S-320CNC Swivel-Head Bandsaw combines intelligent design with user-friendly controls to deliver outstanding performance. With the ability to make challenging cuts that traditional equipment can’t, the S-320CNC enhances cutting precision and boosts overall productivity. Whether you’re in high-volume production or tackling specialized tasks, this automatic CNC swivel bandsaw ensures your operations run smoothly and efficiently, making it the ideal investment for improving your cutting capabilities.

High-Quality CNC Bandsaws for Sale From DoALL Sawing Products

Our S-320CNC horizontal StructurALL® saw includes a Mitsubishi touchscreen to guide you through your most demanding cutting applications. This scissor-style miter-cutting saw also features hydraulically controlled automatic indexing for multiple material feeds, allowing operators to program their desired cuts and collect the finished product in seconds. The 3.5-horsepower screw-driven system provides the power and precision needed for vertical or angular cuts, with adjustability up to 60 degrees in semi-automatic mode.

Other key features that set the S-320CNC apart from other models include:

- A movable control console that enhances operator comfort and safety.

- Full-stroke hydraulic vises that minimize setup time and maximize clamping pressure.

- Automatic overload feed protection that monitors the band drive motor's amperage.

- Cast-steel band wheels for optimal tracking and extended operational life.

- A servo-controlled ball screw indexer system for superior accuracy and repeatability.

Swivel-Head Bandsaw Applications

The DoALL S-320CNC is ideal for fabrication shops, manufacturing plants, maintenance facilities, and tool rooms where precise metal cutting is critical. Its versatility is perfect for low- or medium-production settings requiring consistent quality across various cutting applications. Executing complex miter cuts up to 60 degrees significantly expands this saw's many capabilities.

Common applications where the S-320CNC excels include:

- Precision structural steel fabrication.

- Multiple-length production runs with varied cutting requirements.

- Angular cutting for complex components.

- Parts fabrication for architectural metalwork.

- Tool and die production with strict tolerances.

Benefits of Choosing a CNC Bandsaw for Your Cutting Needs

Investing in the DoALL S-320CNC bandsaw provides many benefits that boost your shop's efficiency and product quality. The state-of-the-art digital controls enhance the cutting process by eliminating manual measurement errors and reducing setup time between projects.

Incorporating this advanced sawing technology into your facility means you'll enjoy other benefits like:

- Productivity: Fully automated operation and automatic indexing capability require minimal intervention while the machine performs programmed cutting sequences.

- Accuracy: Ball screw drive technology and digital angle positioning ensure precise cuts within tight tolerances every time.

- Reduced waste: Accurate cuts and overfeed protection minimize waste and maximize the yield from valuable materials.

- Safety: The movable control console and comprehensive guarding keep operators safely away from the cutting area.

- Longevity: Optimized speed control and automatic material height sensing protect your blade and extend operational life.

Additional benefits include comprehensive support with each equipment purchase, including expert installation services, operator training options, ServiceALL® preventive maintenance programs, and DoALL's exclusive Cut Above 10-Year Warranty®.

Watch the S-320CNC Swivel-Head Bandsaw in Action

Curious to see the S-320CNC Automatic CNC Swivel Band Saw in action? Watch it take on challenging cuts and showcase its incredible performance. See why it's the ultimate choice for precision metal cutting!

Find Swivel-Head Bandsaws for Sale at DoALL Sawing Products Today

Experience the outstanding precision and efficiency that only a DoALL S-320CNC automatic bandsaw can deliver. Discover why industry leaders choose DoALL first for unmatched performance, reliability, and long-term value. Contact us online today for a quote or to request additional equipment information.

Standard equipment and features for the fully-automated DoALL S-320CNC band saw:

- Swivel head to 60 degrees right

- Automatic cycle

- Movable control console

- Rapid head down approach

- Carbide faced saw guide inserts

- Material height sensor

- Full stroke hydraulic vises

- Driven band cleaning brushes

- Ball screw with incremental feed

- Heavy duty counter balance springs

- Cast Steel band wheels

- Fine adjustment head feed control

- Overfeed protection

- Infinite band speed controlled variable frequency drive

- Mitsubishi touch screen controller

- Digital angle position

- Out of stock sensor

- Manual band tension

- Variable vise pressure

- Recirculating coolant system

- Mist band lubricator system

- Work light

- Saw blade guards

- Band door interlocks

- Operation and parts manuals on USB stick

- Recommended band speed chart

- One (1) complimentary DoALL Bi Metal saw blade

- Complimentary DoALL Cutting Fluids package

Details:

- Operator Control Console - Control console can be positioned for operator comfort and safety insuring hands are away from blade at band start.

- Mitsubishi Touch Screen Panel - The touch screen control panel displays cutting cycle indicator, blade tension warning, BRP (overfeed protection) function, band speed, band drive amp load and a list of error messages allowing operator to monitor machine functions.

- Direct Driven Band Drive - Drive is comprised of an electric VFD controlled motor transferring power through a gear reduction unit directly to the drive wheel eliminates belt slippage and gives positive torque to the blade.

- Automatic Cycle - The Automatic Cycle function allows the operator the ability to write and save 20 individual programs containing up to 15 different length of parts eliminating the need to stop the cycle and reset for multiple part sizes saving production time.

- Automatic Overload Feed Protection - BRP function monitors band drive motor amperage stopping head fall when operator set parameter is reached signaling overfeed or a dull saw band.

- Band Wheels - Cast steel wheels insure band tracking and long life. Lay back head design minimizes band twist which causes band fatigue and also allows a smaller footprint.

- Hydraulic Clamping Vise - Full stroke hydraulic vises will minimize setup time and maximize clamping pressure eliminating material movement and tooth strippage.

- Indexer - The vise carriage is guided with two hardened chrome plated rods and is positioned by a servo controlled ball screw insuring accuracy and repeatability also allowing for incremental indexing which decreases cycle time.

- Head Turn Table - The miter function is accomplished by turning a conveniently located lock and manually swiveling the head to the desired angle which is displayed on the touch screen allowing the operator to make miter cuts in the semi-automatic production mode.

- Manual Blade Tension - Illuminating indictor prevents possible error of over/under-tightening the band for maximum cutting rates and band life.

- Band Brush - Driven band brush removes the chips from the blade gullets which would prevent the blade from attaining maximum cutting rates and blade life.

- Counter Balance Spring – Counter balance springs maintain constant head weight throughout the cut keeping the blade tooth load equal aiding in maximum blade life.

- Warranty - One year (parts only) subject to terms and conditions. 10 year manufacturer’s warranty available (DoALL Cut Above 10 Year Warranty).

Saw Blade:

- Width x Length - 1" x 144"

Band Drive:

- Motor HP – 3.5 Hp

- Band Speed - 65-325 fpm

- Band Tension - Manual

Hydraulic System:

- Motor Hp – 1 Hp

- Reservoir Size – 2.5 Gallons

Coolant System:

- Flood coolant & mist coolant

- Motor Hp - .17 Hp

- Reservoir Size – 2.25 Gallons

Indexer:

- Length per Stroke - 19.5”

- Maximum Index Strokes Length - 394"

- Remnant Length - 3”

Floor Space Dimensions:

- W x L x H – 91” x 75” x 60”

- Material Pass Height – 31.5”

- Machine Weight – 1,993 lbs.

Electrical:

- Voltage Requirement - 230V-60Hz-3ph, Wye configuration

- Total Amp Draw (FLA) - 14.7 Amps

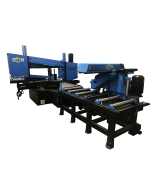

Optional Accessories:

- 3.3 ft. (1000mm) Output conveyor for angle cutting - 15.4" (390mm) roller width - 441lbs./ft. or 200kg/m capacity - has adjustable leg

- 6.6 ft. (2000mm) Input or output conveyor - 15.4" (390mm) roller width - 134 lbs./ft. (200kg/m) capacity - has adjustable leg

- Single fixed vertical conveyor roller - 7.8" (200mm) roller height - Mounts to the RD table

- Single adjustable vertical conveyor roller - 7.8" (200mm) roller height - 15.4" (390mm) roller width

- 10 ft Medium-duty idler conveyor 13" between frames. Roller capacity 850 Ibs

- 5 ft Medium-duty idler conveyor 13" between frames. Roller capacity 850 Ibs

- Front and rear hydraulic vise nesting - set of 2

- Conveyor support

- Wear parts service kit - contains wear plates, guides, band brushes

- Chip pan with drain

- Magnetic wand chip remover

- A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards

- Additional USB stick of manuals

- DoALL Cut Above 10 Year Warranty Annual Investment