Sawing Machines

Industrial Bandsaw Machines

Are you looking for a sawing solution that offers precise and efficient cuts, ease of use, minimized production waste, and operator safety? If so, an industrial bandsaw machine may be the answer.

Perfect for both straight and angled cuts, these machines come with various features to make the sawing process straightforward and hassle-free. Depending on the model you choose, you can enjoy a host of features like hydraulic and touchscreen controls and adjustable heads.

If you're on the hunt for a quality industrial material or steel-cutting saw machine, our experts at DoALL Sawing Products can work with you to find a solution. Discover the various industrial saw machines we offer and find the right option for you.

Solutions for ALL Your Sawing Needs! There's Nothing We Can't Cut!

DoALL industrial metal cutting bandsaws combine maximum performance and versatility with guaranteed precision.

Leighton A. Wilkie founded DoALL® Sawing in 1927. Wilkie also invented and manufactured the first metal cutting bandsaw in 1933. DoALL is known for machine longevity and saw reliability. We continue to be a global leader for all your sawing needs! We provide manual, semi-automatic, and automatic metalworking bandsaws.

What Are Industrial Bandsaws?

Industrial-grade bandsaws are powerful tools that easily enable you to cut consistent pieces or irregular shapes in metal. They feature a sharp, thin rotating blade that allows you to make smooth, efficient cuts, saving time and effort.

An industrial bandsaw machine is also compatible with an assortment of blades — you can make quick changes to ensure the best cutting results for your applications and material.

Bandsaw Metal Cutting Machine Capabilities

Bandsaw machines are an excellent choice for operations that require maximum flexibility. Use them to make high-precision cuts on materials ranging in size from a fraction of an inch to up to 5 feet, depending on the specific machine's capabilities. Bandsaws can cut tougher metals like nickel-based alloys and even titanium with minimal effort.

They can also cut various shapes from pipes, plates, tubes, and solid bars. If you need to cut many identical pieces from one long piece of stock, a bandsaw is typically the best tool for the job.

Other bandsaw cutting machine advantages include:

- Accuracy: Because your work is more visible when using this efficient metal sawing machine, you can follow the cutting line more easily. There's also less chance that the blade will wander when working with thicker materials.

- Safety: Bandsaws provide a low-impact cutting solution. The blade cuts in a downward direction, which helps hold the workpiece securely on the table and reduces the risk of a potentially dangerous kickback.

- Affordability: Bandsaws typically provide a lower-priced machine sawing solution than precision circular saws and other cutting equipment. You can achieve superior results without stretching your company's budget.

DoALL Offers a Variety of Bandsaws

At DoALL, we strive to meet the machine sawing needs of customers in various industries by offering a wide range of high-quality bandsaws for sale. Our featured items include:

1. S-500CNC Miter Bandsaw

One of our numerous automatic sawing machines, this hydraulically controlled product can meet the needs of automotive and power sports production shops, tool and manufacturing plants, mid-sized fabricators, and more. It's the perfect choice for companies seeking to automate their parts production processes. Its automatic indexing capabilities can support multiple material feeds.

The S-500CNC features digital touchscreen controls, fully automated operation, a ball screw feed, a mitering saw head and a flexible bandsaw head. Because it includes a Mitsubishi digital controller, you only need to remove the cut material.

Adjustable to 60 degrees in semi-automatic mode, the S-500CNC Miter Bandsaw makes angular and vertical cuts a breeze. Enjoy a versatile, easy-to-use solution that reduces production times while increasing operator safety.

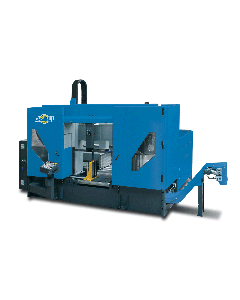

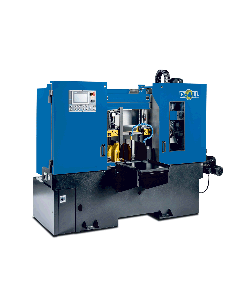

2. DS-600SA Dual-Miter Semi-Automatic Bandsaw

This powerful, efficient saw works in fabrication shops, repair facilities, industrial manufacturing plants, and other facilities that cut tubing and structural shapes. Ideal for straight and angled cuts, the dual-swivel head enables you to make cuts at up to a 60-degree angle in either direction.

The addition of a Mitsubishi digital controller makes it simple to confirm precise cutting angles and simplify part production. Some other features include:

- A mist band lubricator system.

- Hydraulic variable vise pressure.

- Digital touchscreen controls.

- A programmable material height sensor.

- A recommended band speed chart.

- A complimentary cutting fluids package.

We also provide a range of optional accessories, allowing you to customize your machine for specific cutting requirements.

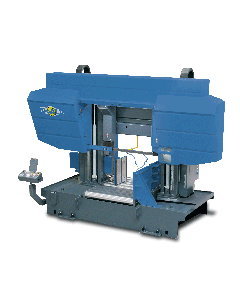

3. DS-280M Dual-Miter Manual Bandsaw

This manually operated sawing machine provides a practical, cost-effective solution. Use it for cutting angular and vertical material in low-volume piece production applications. You'll have the flexibility to cut at two speeds. You can also choose from an assortment of accessories to customize the equipment to your specific requirements.

The DS-280M comes with a 45-60-degree dual swivel head, push-button control panel and head feed and fine adjustment control. These included accessories can help your facility complete low-volume projects with minimal space and hassle:

- A band-driven cleaning brush.

- Saw blade guards.

- A recirculating coolant system.

- Band door interlocks.

- A free cutting fluids package.

- Parts and operations manuals.

- A complimentary bi-metal saw blade by DoALL.

Find Industrial Sawing Solutions at DoALL Sawing Products

When you partner with DoALL, you get an unbeatable combination of high-quality products and exceptional support. We have over 97 years of industry expertise, and we're the only company on the market that offers all four aspects of sawing solutions — machines, blades, fluids and coolants, and services.

We also offer financing options to make your bandsaw purchase more affordable and warranty coverage for your protection and peace of mind. We also include installation and training for CNC and automated machines.

Whatever your cutting requirements and project specifications, our experts are ready to help you find an industrial bandsaw that meets your needs and exceeds your wildest sawing expectations. Request a quote for additional product and pricing information today.